Process water treatment …

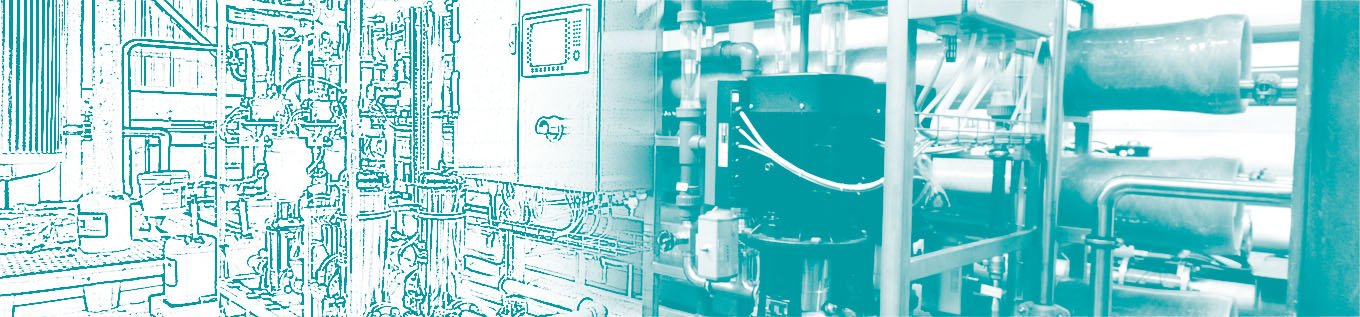

… of a special kind: computer-controlled, electrolytic manufacturing processes are increasingly being used for shaping high-strength nickel-chromium-based stainless steels. Electrochemical machining, or ECM for short, guarantees residual stress-free material removal, smooth transitions and a smooth surface. The removal principle is based on anodic metal dissolution by electrolysis.

A highly saline electrolyte solution is used as “process water”. Due to the high density, the material behaviour is not comparable with other aqueous solutions. Chromium (VI) and nickel as well as other metal particles must be specifically detoxified and removed by the process water treatment after manufacturing in the machine tool. After a multi-stage cleaning process, the electrolyte solution is returned to the manufacturing process. Narrow tolerances for conductivity, temperature and pressure must be maintained, as must the absence of particles in the electrolyte. Once all parameters have been reliably met, nothing stands in the way of efficient machining of the special steels.

Herbert Bassek

Head of Sales

mobile: +49 151 40649668

herbert.bassek@bws-water.com

What makes us special

- Multiple realised plants for central electrolyte treatment according to the ECM and PECM process

- Safe handling and conveying of reduction agents

- Dissolving stations for electrolyte

- Sludge dewatering

- Cleaning service for UF modules